Another tool in fighting dye migration is “Poly white.” We use Rutland’s “Super Poly White” but other companies have similar formulations. In some ways the game has been upped. Once you could sometimes use cotton white on 50/50’s and a white for 50/50’s would always work. Now sometimes we can’t even count on the dye stopping of 50/50 whites on 50/50’s, and on a few occasions we have not only needed poly white for 50/50’s, we have needed to use a barrier grey to stop bad dye migration. You can cry about this situation, but your tears will just dilute the ink and make the problem worse…

Figure how bad the dye migration is and use whatever you have to.

For bleeding 50/50 shirts, bleeding garment-dyed shirts, or definitely bleeding polyester shirts you want to consider using poly white.

Pros:

• No grey under base needed. You have to hope it works when you just don’t have enough stations for grey or you need a softer hand than the grey will give you.

• Bleed resistance is much better than a standard low bleed white that might be meant for 50/50’s.

• It can be printed through higher mesh counts than barrier grey inks.

Cons:

- With certain colors of cotton shirts, usually light greens or blues, you can get ghosting if the shirts are hot. Basically some chemicals in the poly white bleach out the shirt placed on top of them. This can be avoided with long outfeeds on your dryer, turn temp down and belt speed down, make multiple stacks of shirts, or use of fans to cool the shirts.

- The hand and printability usually suffer for better bleed resistance. Poly white prints better and feels better than barrier grey inks, but feels worse and prints worse than low bleed or cotton whites.

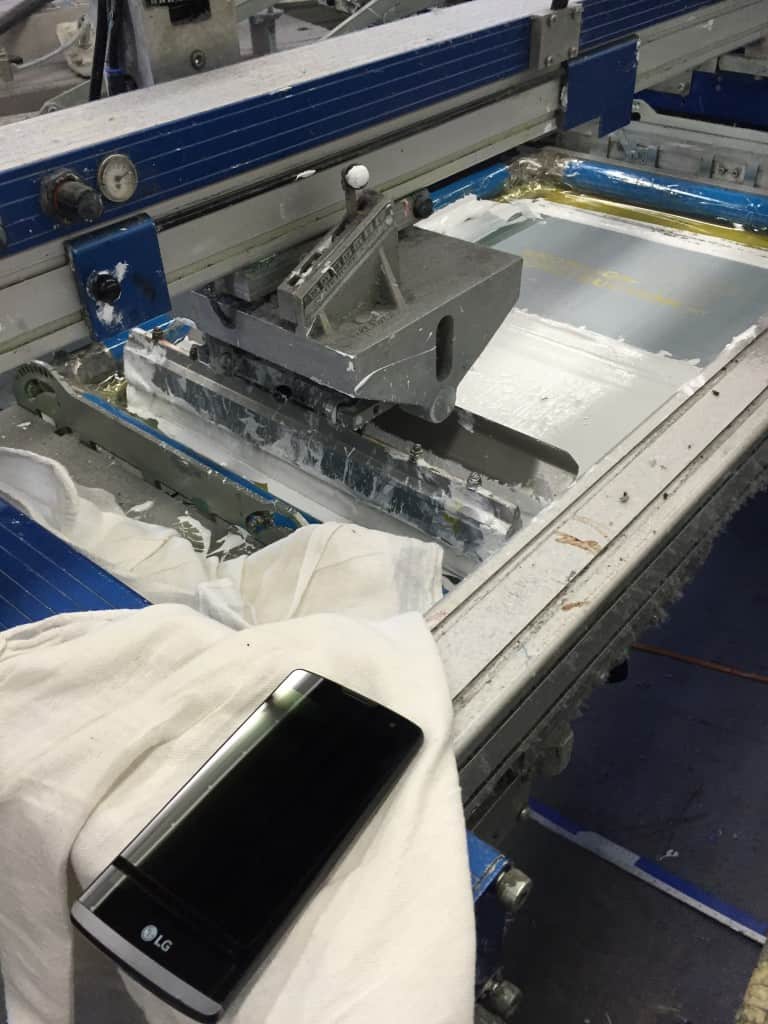

Here we print with some Super Poly White ink on a 100% polyester shirt. The photo of the shirt was taken a week later and it still is super bright white, no dye migration whatsoever.

Comments