Garrett Kaule is one energetic dude. He prints and prints and when he isn’t printing he is communicating. He has a lot to say to his customers in the Pittsburgh area, and he communicates like crazy with his screenprinting brothers and sisters. He’s the straw that stirs the drink. We love his enthusiasm. We asked him to send some photos and words regarding his recent installation of his first automatic press. Here is Garrett in his own words and photos:

Rick,

Sorry I forgot to add some words. Let me know if this will work.

From day 1 to day 3 of the install we were up and running on day 3 printing our first job. Hirsch really came through, from Rodney doing the install to Robert training us how to use the new press everything went better than we could have expected.

The scariest part of the install was when the press was being unloaded off the semi truck. I almost had a heart attack. Of course my Dad was playing it cool the entire time although I knew he was sweating!

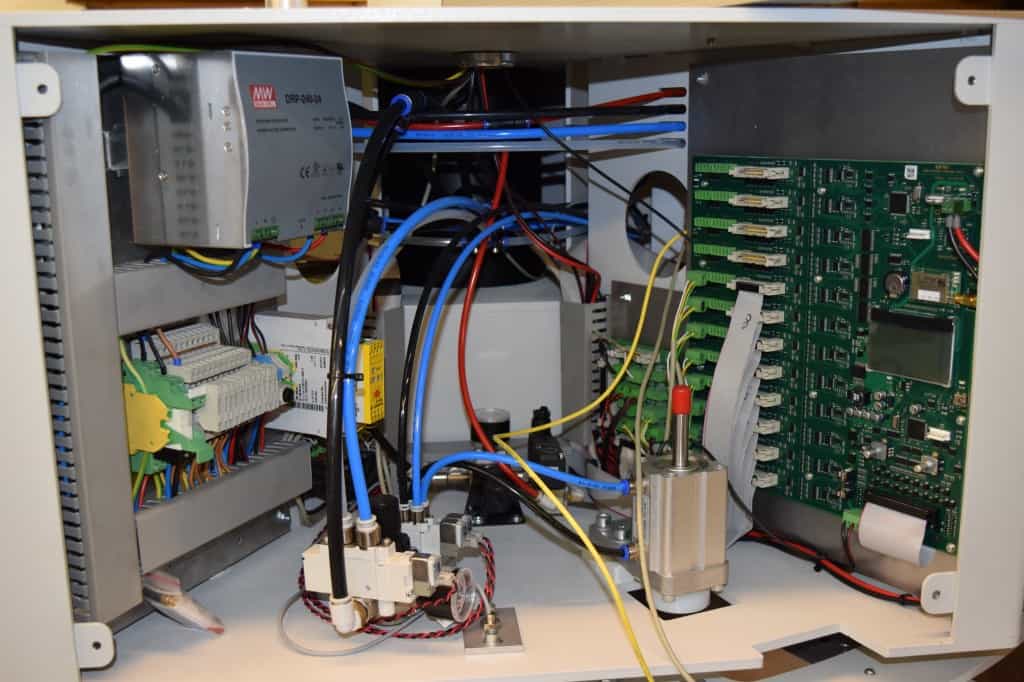

When our X-Type plus was uncrated for the first time, we knew it was the right press for us. The first press we laid eyes on at an ISS trade show 4 or 5 years ago was the MHM. I’ve watched a lot of videos online of presses being installed and everything looks so complicated with 1 million wires sticking out everywhere. The main thing we noticed was that the press was basically built when it arrived. At least that was the way it appeared to us.

From an engineering standpoint we believe that MHM presses are light years ahead of the competition. Some of the best screen printers in the world are printing on MHM’s.

I’d like to thank Rick and his press operator for helping us with a few noob questions we had about printing on the automatic. I figured it would be best to ask the pros!

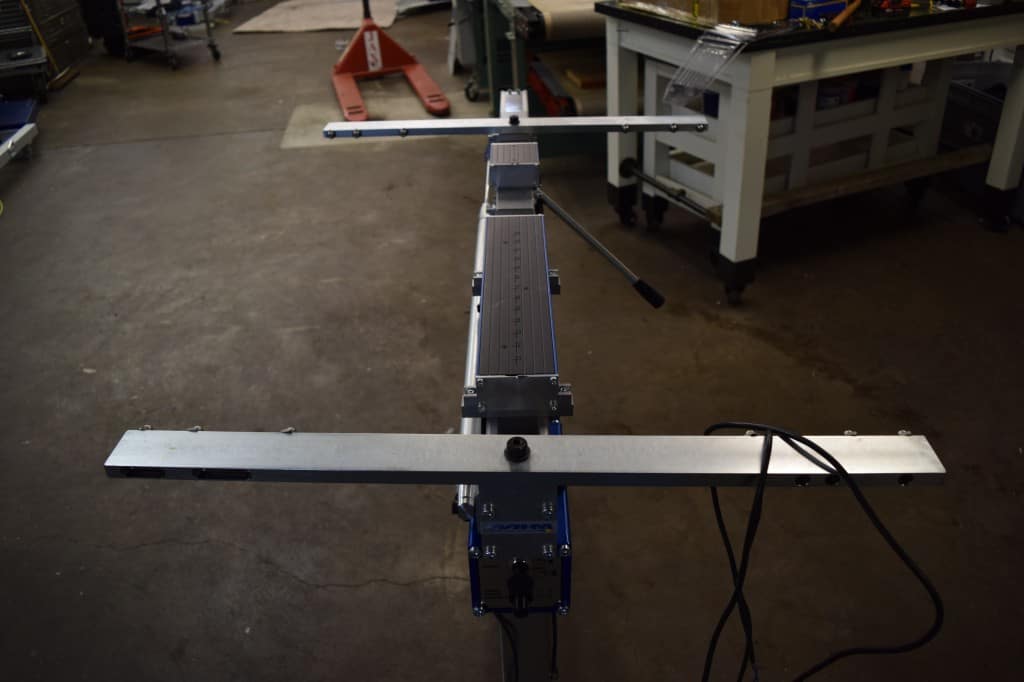

Our first 5 color simulated process turned out excellent. The film positioning unit makes setting up jobs extremely fast and accurate.

Thanks to the Ink Kitchen for sharing our story. You guys rock!

GK

Comments