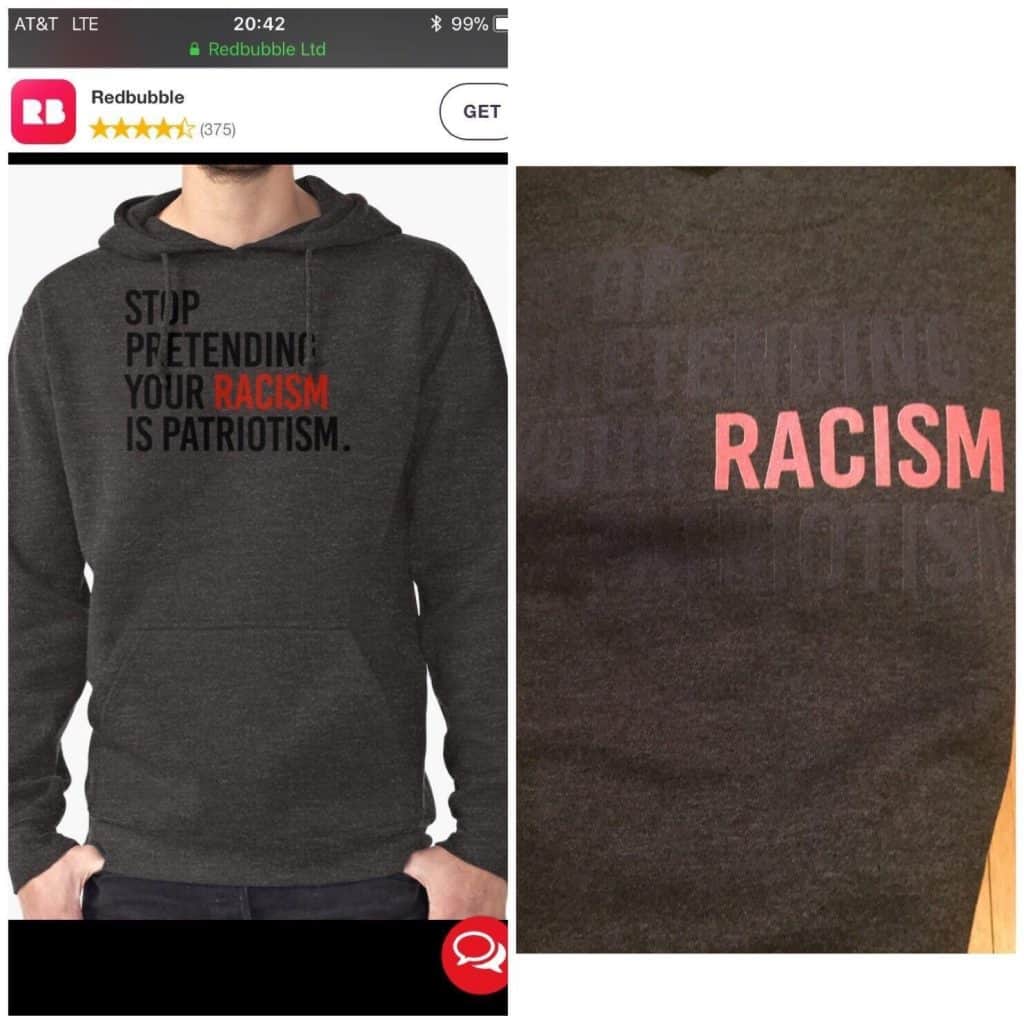

This “expectation vs. reality” example shows that this “simple” and “clever” concept is actually not so simple to achieve (and maybe not that clever?)

We get a ton of requests to print black ink on a black shirt. To achieve the effect, the following considerations must be taken into account:

First, and most importantly, what is the designer/customer actually trying to achieve?

- Typically the designer’s concept is to print black ink which will appear slightly darker than the black garment itself. This is not always possible based on the garment brand/style/color.

- Sometimes the designer is looking for a minimal color contrast but rather a contrast in the appearance of the ink surface vs. the shirt surface (i.e. a sheen to the surface of the ink which will contrast with the flat finish of the garment) to create the effect. Here we have many options such as black/clear foil, gloss resurfacing, specialty inks, etc.

- Sometimes the designer is going for a tactile effect, think high-density, puff, gel, etc.

The main point is work with the customer (whom likely does not understand the print options/limitations and may not be able to articulate what they are trying to achieve) to gain an understanding of the desired effect. It is our job as printers to educate/direct the customer based on our experience and the parameters of substrate/budget/etc. what they have for options on our end to achieve the printed piece they imagine.

If you just take the job and print black ink that you have lying around on whatever black shirt is supplied or you blindly select, you will be a candidate for mis-print monday. If you don’t consider exactly what garment and exactly what decorating technique/material then you are mostly likely going to have a failure, black ink on a black shirt sounds simple but it isn’t.

Comments