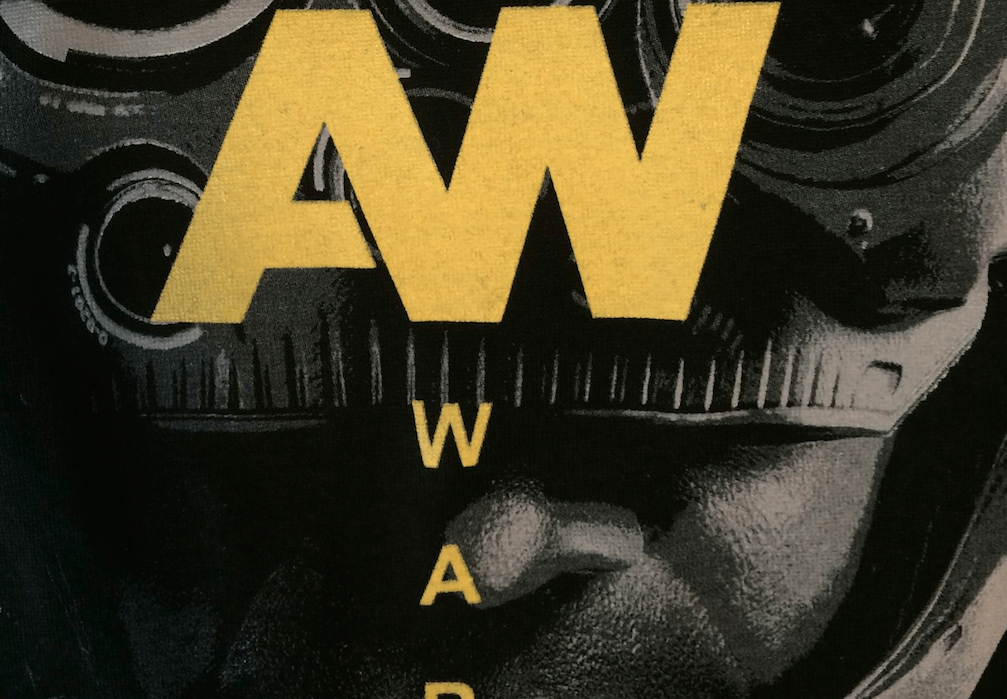

We’re very cautious to avoid “bleeding” and “dye-migration” when it comes to printing 100% poly and poly-blend fabrics. We use poly white plus a barrier gray when under-basing 100% poly and we use poly white plus a standard low-bleed white when under-basing blends. We drop our oven temp and cure time, and we are careful not to “stack hot”. Sometimes though it seems that all the precaution in the world isn’t enough. Last week we printed a small run of tees which were a 65% poly / 35% cotton blend. The back of the shirt was printed on Wednesday at the end of shift. All the typical precaution was used and this 1-color w/ double base print looked great. On Thursday morning while approving the front graphic it was noticed that the “yellow doesn’t match the yellow on the back of the shirt”. Oh s#%t! This was indeed a case of dye-migration as our nice soft gold color had turned to a muddy greenish-yellow. Rick did a good post recently on a simple testing solution to this problem, I’m thinking we will incorporate this precautionary measure as well. Thanks Rick!

Comments