A garment dyed shirt is a wonderful thing, comfortable and they come in beautiful colors. However, there are a few limitations that go along with these shirts and one is that you cannot remove the ink if you make a mistake.

Best practices for garment dyed shirts:

1. Use a good emulsion

2. Get a thorough exposure

3. Carefully “pinhole” the screens and put tape on the back of the screen where there is no image as insurance policy.

4. Make sure everybody’s hands and shirts are clean before they go anywhere near the garments.

5. Good housekeeping in general helps, particularly around the load and unload stations. No ink except in your screens!

6. Customer service may want to inform customers that they may have to live with small pinholes (spots.)

7. Contract customers have to accept a higher imperfect rate or if you are buying the shirts you have to figure in higher spoilage on the garments.

All of this because you cannot use a dry cleaning gun to get out pinholes or spots of ink.

Maybe not what you wanted to hear, but that’s the story.

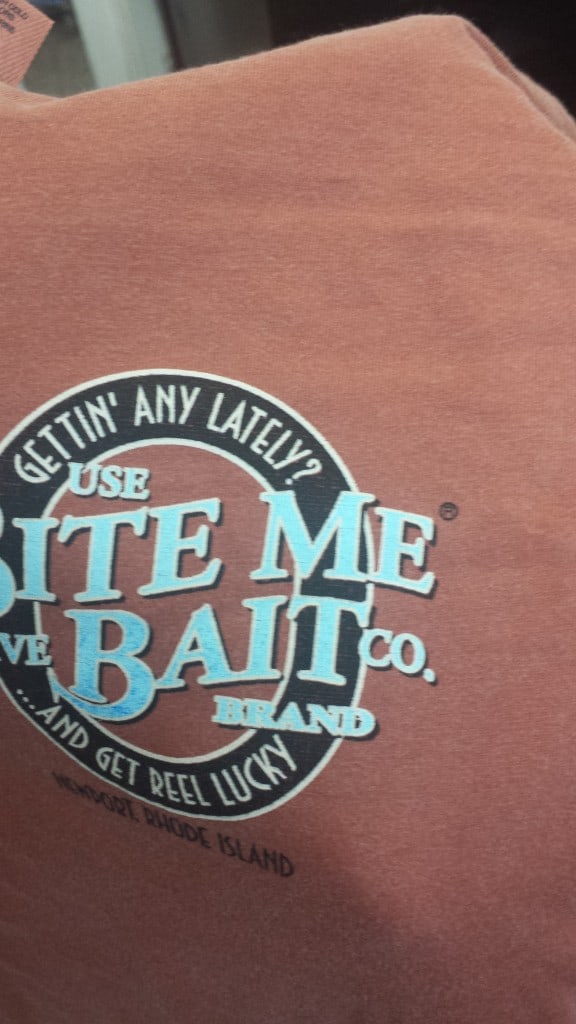

See below and as I try to take the black Trademark symbol off the shirt with my spot cleaning “gun” and it takes it off but also takes the dye out of the shirt. Regular plastisol on most regular shirts this would work, but not with garment dyed shirts.

Comments