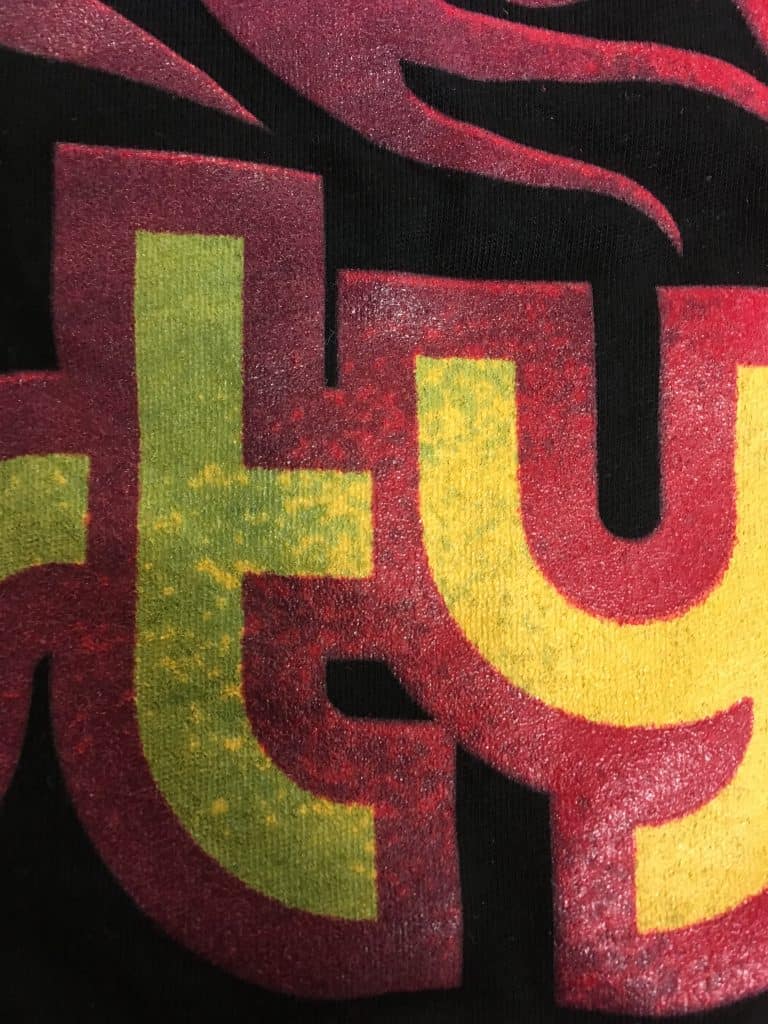

From our pal Brett Bowden at Printed Threads in Texas comes this tale of woe. It doesn’t seem right to publish a story about a “bedeviled” Christian shirt on Christmas (this coming Monday) so we put this out today, a Friday.

The joys of printing on Triblends (cotton, polyester, rayon) that are 100% black…

Our job with Triblend printing is that we’ve got to make the print as soft as possible, because the shirts are soft… AND we have to make sure the dye in the poly doesn’t bleed. That’s super easy, right?

We were running this Triblend job on 2 presses and using both of our dryers (neither of which is a split belt.) Because we were going to use a higher temperature because we were running regular plastisol at the same time, instead of using low cure inks, we opted to use a barrier gray to keep shirts from dye migrating into our inks. In this particular instance, we were printing Barrier Gray, Flash, Underbase White, Flash, Red, Yellow.

The results should have been good, but in the end they were not and here is why:

What happened was that the barrier started clogging up the mesh. Since we had a white underbase after the barrier grey, the colors still looked good when the shirts were coming off press. An hour later we noticed the dye starting to migrate. That is not a good feeling. That is a terrible feeling when you realize you have ruined a couple hundred shirts that cost over $5 each.

What was the problem? We use a couple different Barrier Gray inks. One is stronger and stiffer than the other and one is softer and easier to print (and doesn’t block dye migration as well, particularly if you overheat it.) At some point when screens were scraped in the reclaim area, the 2 grays got mixed into the same bucket.

Lessons learned:

Label your screens clearly and your ink buckets clearly

Keep an eye on your screens to make sure they are clearing

Hard lesson. Ouch.

Wouldn’t printing a barrier base ruin the soft hand feel on the triblend shirts? How did you end up getting the print right? Did you run it the same way on the reprint?

We print a lot of triblend shirts and struggle for all of the same reasons.

Tom and I both make extensive use of Rutland’s Endurance Grey which is not as harsh as Barrier Grey. Both easier to print and softer hand, but blocks most dye migration.