Discharge printing is getting more and more popular as a way to produce soft prints on soft shirts. It doesn’t always work.

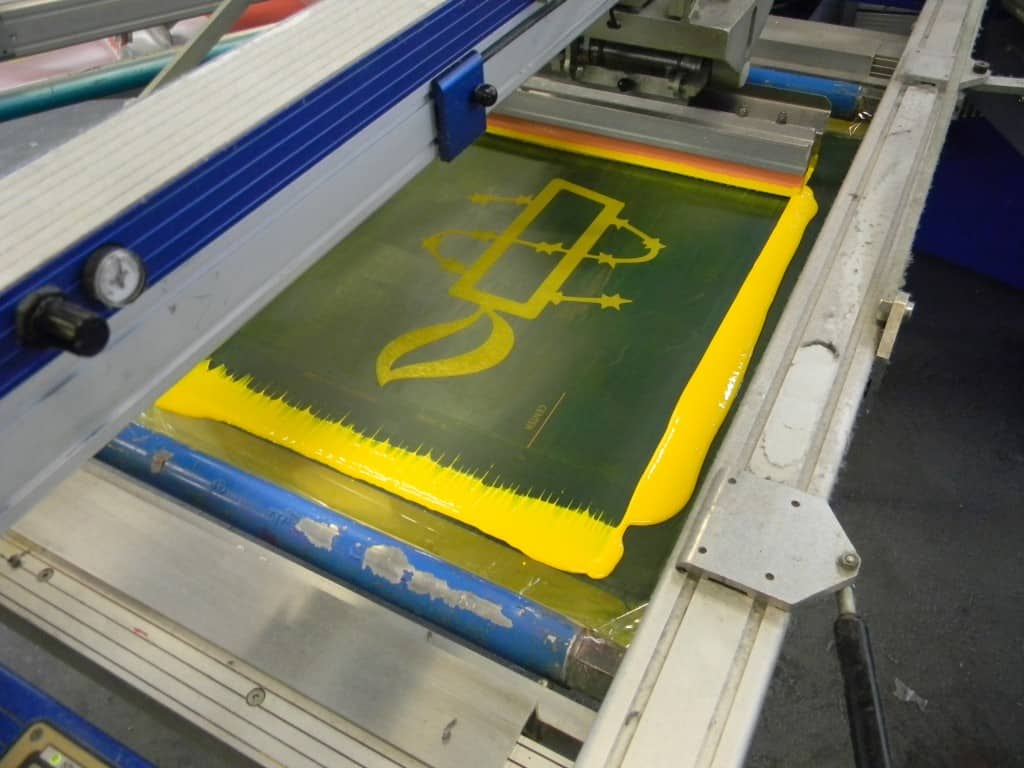

The process is that the discharge agent in the ink combines with water and heat to neutralize the dye in the shirt. The color of the ink then goes into the fabric and there is no need for the usual underprint of white ink.

It is tough to color match because until the shirt goes in the oven it doesn’t look like much. The heated time in the dryer is required to finish the process. So you mix up the color, add the discharge agent (which only lasts one day or less,) and then print it and send it down the dryer before you can see what you really are going to get. That all is difficult enough, but in fact not all dyes are “dischargeable” and it isn’t a quality issue. It just is a hand and glove type of thing, some work chemically and some don’t, so you have to try a shirt before you know if it will discharge. You can print the shirt with a perfect ink mix and perfect technique and still it will not work if the shirt doesn’t work. Only cotton dyes work, so that eliminates quite a few shirts, but beyond that you have to test.

Here are results of the same print on a variety of shirts. Royal blue and kelly green dyes tend not to discharge. The burgundy colored shirt is a tri-blend and the cotton in it discharges but the polyester and the rayon do not. If your customer wants you to discharge print a tri-blend shirt, they either need to be told no, or they need to be fully aware of the mixed result that you get (which can in fact be a look that some people go for, but it isn’t something you do color matching on.)

Comments