I just joined yet another screenprinter’s group on Facebook. The groups are good ways to share knowledge with your peers. They also are a good place to share complaints with each other, since our families, friends and co-workers long ago stopped wanting to hear about such things.

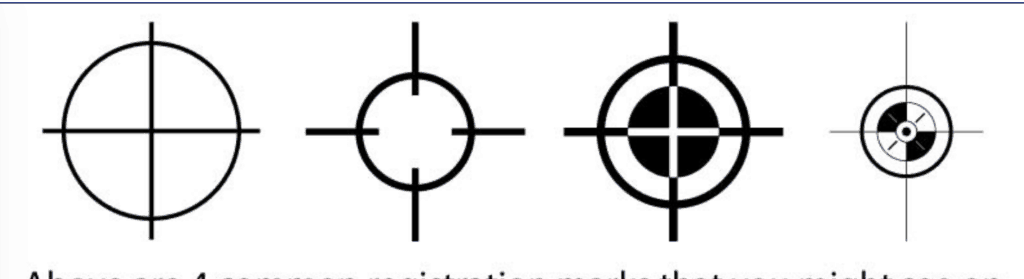

This group had an interesting initiation, to keep it to printers only. They had three questions and one was, “what could cause a registration issue on press?”

I’ll share my answer and elaborate here as well:

- The main shaft of the press: you are usually doomed if your job won’t register and it is a fundamental press problem. The main shaft can be bent or loose and this cannot usually be overcome in any very satisfactory way.

- Screen clamps and/or pins on the press: If anything on the press is not holding the screens where they belong, that will cause registration problems. Loose clamps or on MHM presses it would be loose pins.

- Registration blocks/forks: If the forks, rollers or anything to do with whatever has your platens line up with your screens have an issue, you are also doomed. This has to do with initial set up and regular maintenance of your press. Worn blocks or rollers will eventually need adjustment or replacement.

- The mechanism that moves your screens during registration: The micros, the screws, the threaded rods or whatever you use to move the screens into place must be right. If they get worn or bent they will cause registration issues. Many shops use a hammer to just move that last little bit of the screen into register. It works for the moment but eventually will screw up your machine and it will get loose. Check for wear on anything threaded.

- Platens that are not level: If any one of your platens is not level you will have registration problems, both on that platen and with ink from the back of the screens at that bad platen hitting shirts when they are on the other platens. The cure is either to level the platen or skip it by putting a scrap shirt on that platen, although that sometimes can still be a problem.

- Platens that are not parallel to each other: If your platens are not all on the same plane, you will have registration problems. Platens both have to be level, and also parallel to each other (all the same distance from the ground.

- Platen Adhesive: This is one of the most common problems causing registration problems. Bad adhesion can be due to inadequate application or using a lousy adhesive (particularly using crap ones when flashing.) Basically if the substrate moves, you will have registration problems big time.

- Bad flashing: Inadequate flashing can sometime make the wet screens pull up the shirts off the platens. Inadequate flashing can also leave a color too wet and it will smear and cause registration issues that way.

- Overflashing: Sometimes on certain garments if you overflash you can shrink the garment and that will cause registration issues. This is particularly true of nylon bags and nylon jackets, though other fabrics can also have issues. This is rarely a problem on cotton or 50/50 shirts but it can happen.

- Bad art: Make sure your art was done properly or you have no chance of being in register. Gutters and butt registration points particularly have to be done correctly.

- Ink that is too thin: If your ink is too thin it can run out from the edges of the print area and cause registration problems. This is particularly true with water-based inks but thinned out plastisol can also have issues.

- Bad films: This is another common problem and if your films don’t register, on press you have no hope. Some film is unstable if you print big areas of black, particularly thermal printers and it will shrink. Some film methods have registration issues on tight jobs if you have films that printed out and you changed rolls in the middle of that printing. Some film methods can have issues if you do “nesting” and don’t print all the images in the same direction, i.e. some vertical and some horizontal. In your effort to save money on films, you ruin them all.

- Poor contact of film to screen: If you have a blanket or vacuum issue then the films will not be properly tight to the screen when exposed and will cause registration problems when you get to press. The films will line up when you look at them, but on press it won’t register.

- Over or underexposure of screens: This would not be the first place you would look but you might get the edges to be undercut if overexposed or soft if underexposed and that might look like a registration problem on press.

- Bad screen tension: This is one of the most common problems. You don’t need screens at 60 newtons to do a decent job, but if you have no tension or uneven tension you probably will have registration issues. Your choices are only this: retention your roller frames, buy an expensive screen stretcher and use it, or send screens back to somebody to restretch. We have a Newman roller table (and use it,) Tom sends his frames back to GSF. I know Saati makes a good stretcher. Just because a screen still has mesh on it doesn’t mean it is useful. Get a tension meter, otherwise you are guessing.

- Wrong mesh: You can have registration issues if too much ink is pushed through the screen and that can be from using too low of a mesh count.

- Bad Emulsion Coating: I recently heard someone say they used as little emulsion as possible. This is a bad idea. Work with your emulsion provider to get a consistent and adequate coating of emulsion on your screens. Particularly too little emulsion and you won’t hold good edges and this will give you poor registration between colors.

- Too Much Squeegee Pressure: If you push too much ink through the screen by having the downward squeegee pressure set too high, it will affect the registration.

- Too Much or Too Little Off Contact: Without getting to deeply into this, too little or too much off contact will cause registration issues.

- Choice of Squeegee Blade and Its Angle: Too soft of a squeegee might push too much ink through or not give you a crisp enough print which will give you registration problems. Too hard and you may drag the mesh. Too much angle will also push too much ink, and not enough may pull on the mesh.

- Warped screens: If your screens are not flat and level you will have registration problems for sure, particularly on large images.

- Direct to Screen clamping: If you have a DTS unit make sure the screens are properly mounting.

- Poor screen tension: If you don’t have good screen tension your mesh will drag under the squeegee pressure and cause registration problems. This is one of the most common reasons for registration problems

- Clamping: On most presses you loosen the screens to register and then you clamp them down. The clamping process then usually can move the screens and puts them out of registration. The only press that doesn’t seem to do this is the MHM’s we have, which basically register in a sort of locked position and then just go to super locked position and they don’t move. Most of the others move and you can get used to how they move when clamped but you can’t totally avoid it.

- Operator error: Make sure you really have registered properly, don’t be too quick to blame some other part of the process.

So many variables, you can see why having a system in your shop is so important. If you want a priority list I would say proper films, good screens, and press maintenance.

Great article. Stop blaming and start solving your issues.