We took some ink just sitting on the shelf (295C) and made it into an ink we needed to print today (539C) We test drove the Rutland recycling system within their DMX software and it worked out great. This is no cure for getting rid of all the ink we all have sitting around, but it is a pretty great tool.

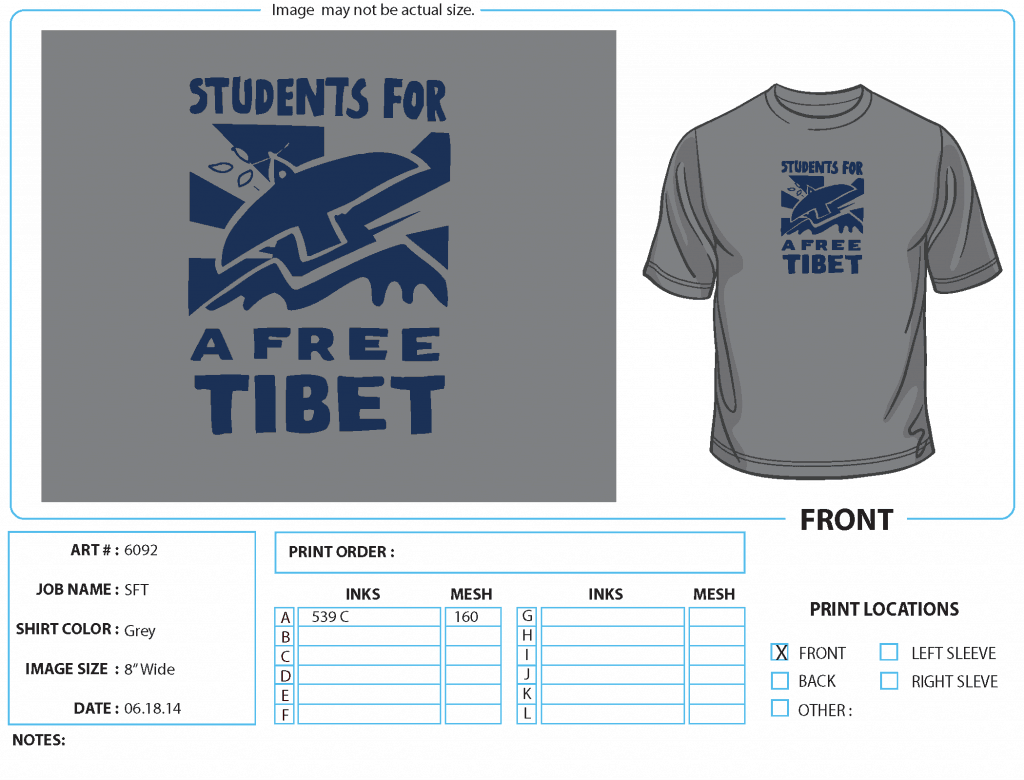

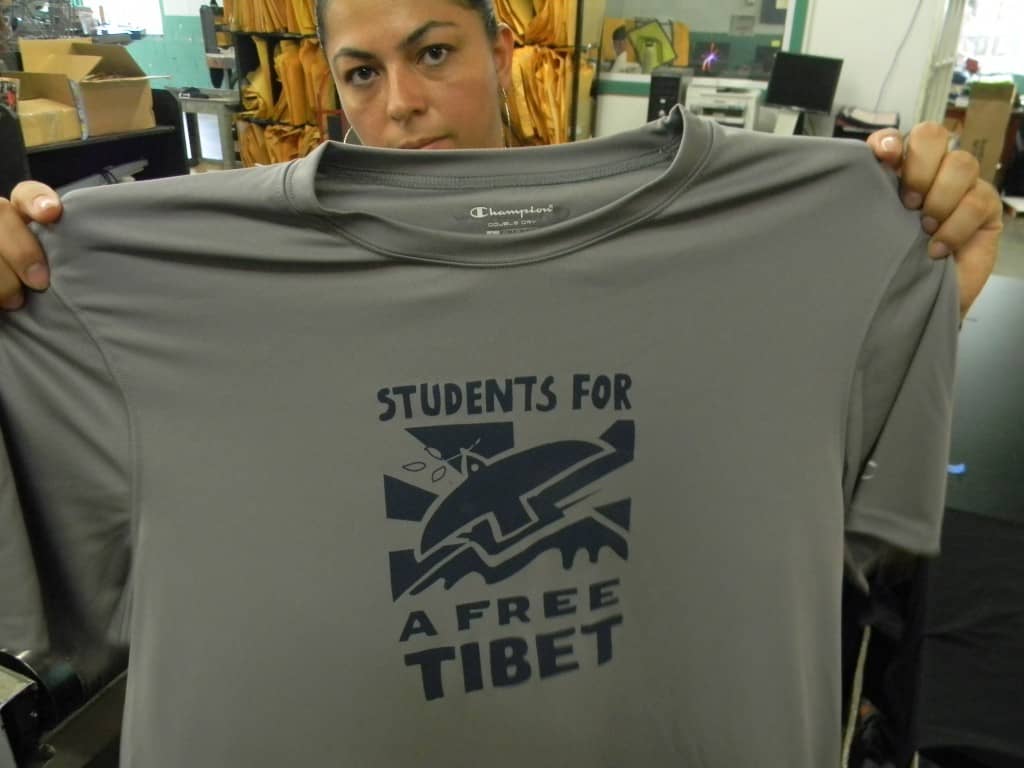

Here is a job that called for an ink to be mixed

At Mirror Image we have literally walls of mixed inks of a wide variety of Pantone colors and there are so many reasons you want to get rid of it:

– Ecologically speaking, using up ink is even better than making the most green ink imaginable

– Ink costs $60 per gallon or more and seeing it sit there is like watching 100 dollar bills on fire

– Getting rid of waste ink cost beaucoup bucks

– It is taking up space, it needs to cycle right off the shelf

– It is faster to use what is right there than order new and receive it in

Here’s how it goes down:

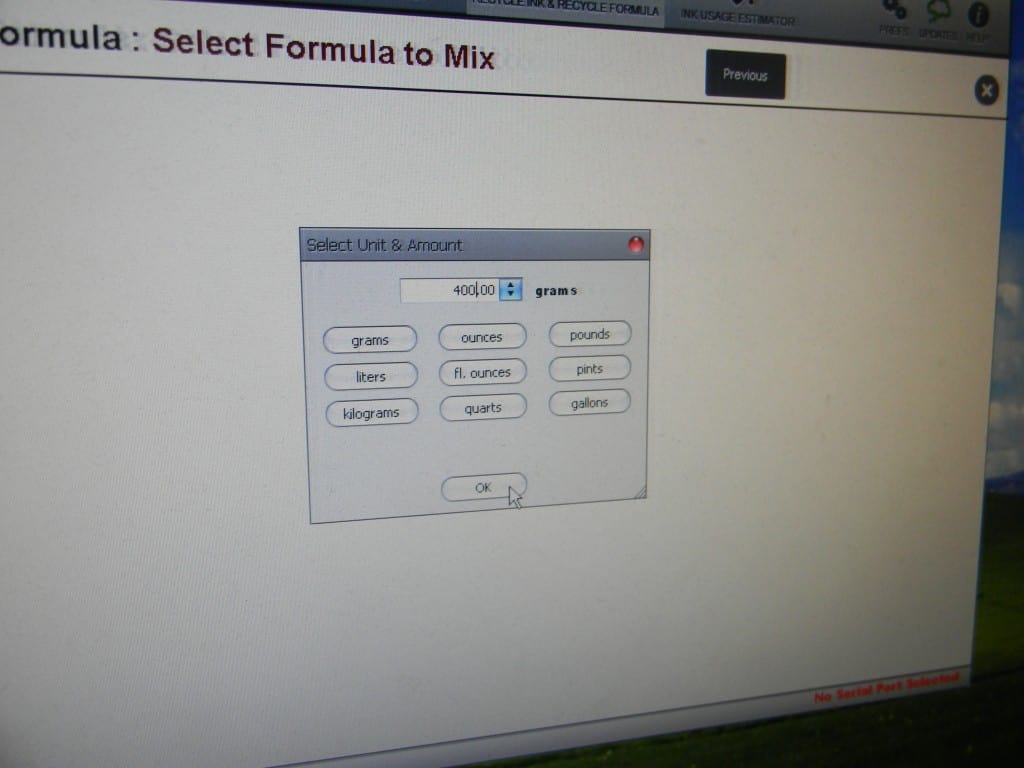

We opened the DMX software of Rutland. For any customer that uses their ink the cost is nil, nada, nothin’.

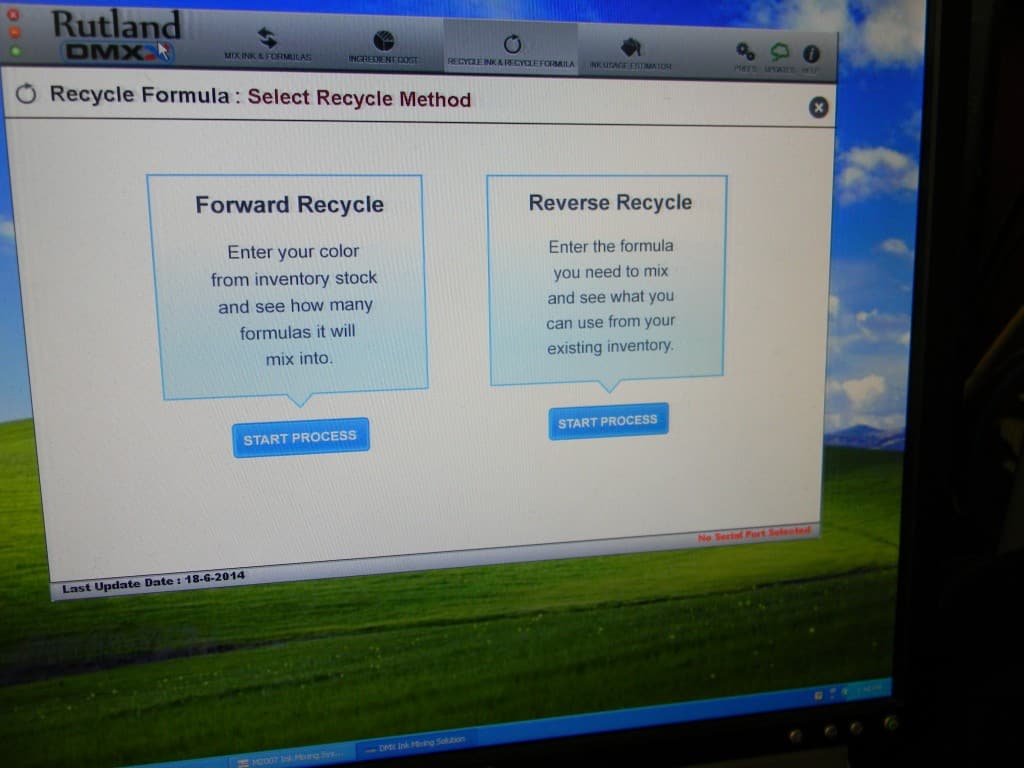

Then we went to the Recycle section to the Reverse Recycle section.

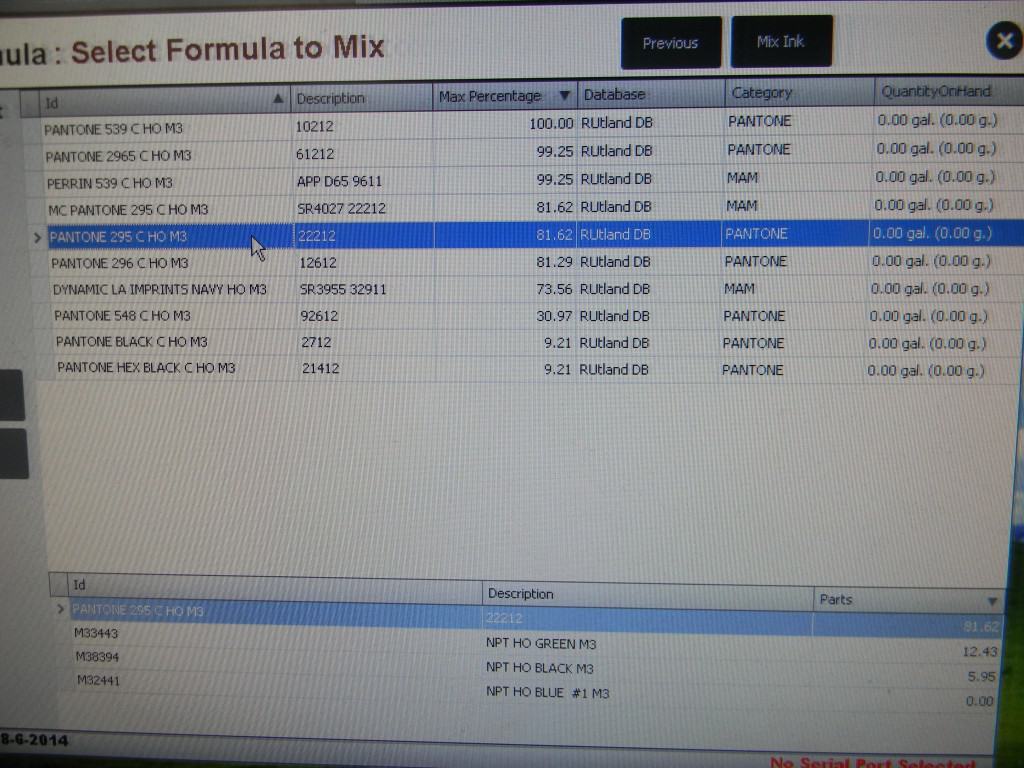

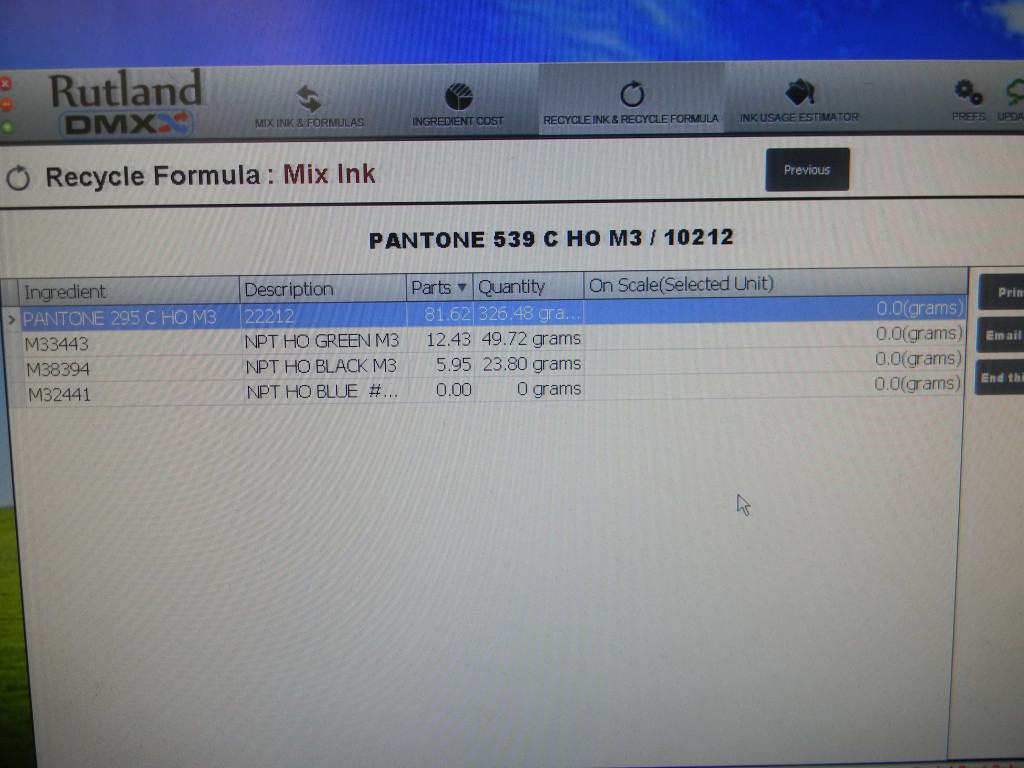

Then we entered the Pantone color we had to make, 539C, and found from the list of inks, we could make it from 295C, which we had sitting on the shelf. In fact 81.62% of the new ink would be from the old ink.

Then we got the formula for using 295C to make 539C.

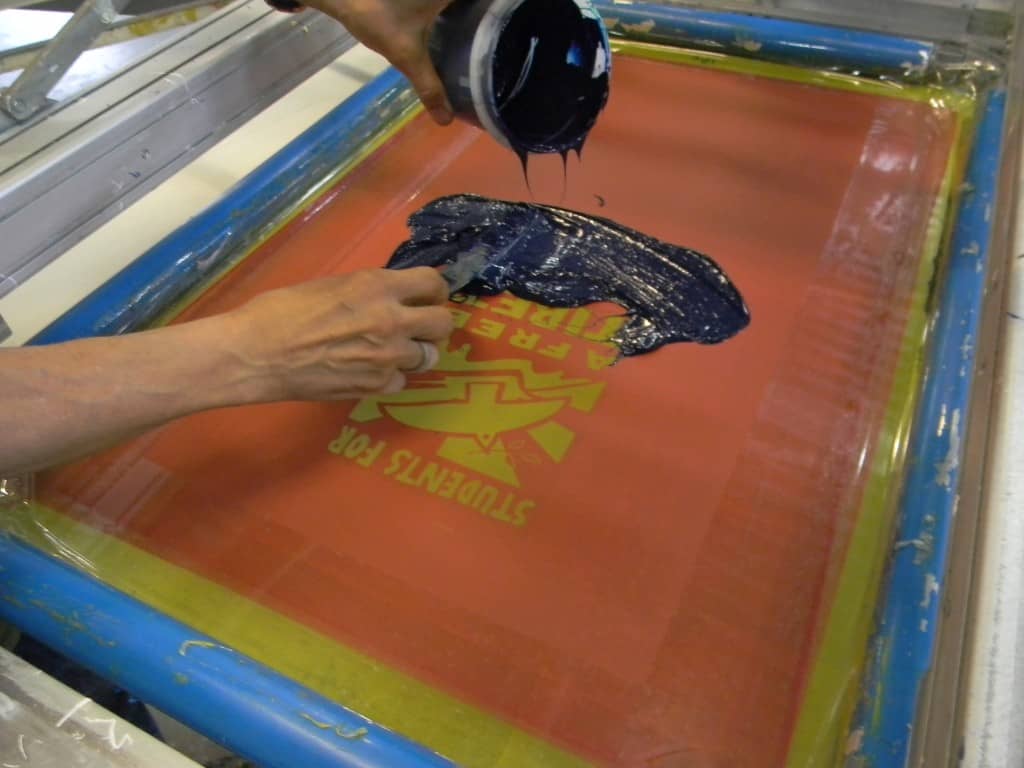

Then we mixed up the ink according to the formula. We could use up the 295C at > 80% of the ink and then added the specified amounts of mixing green and black.

Thoroughly mix up your finely measured ingredients

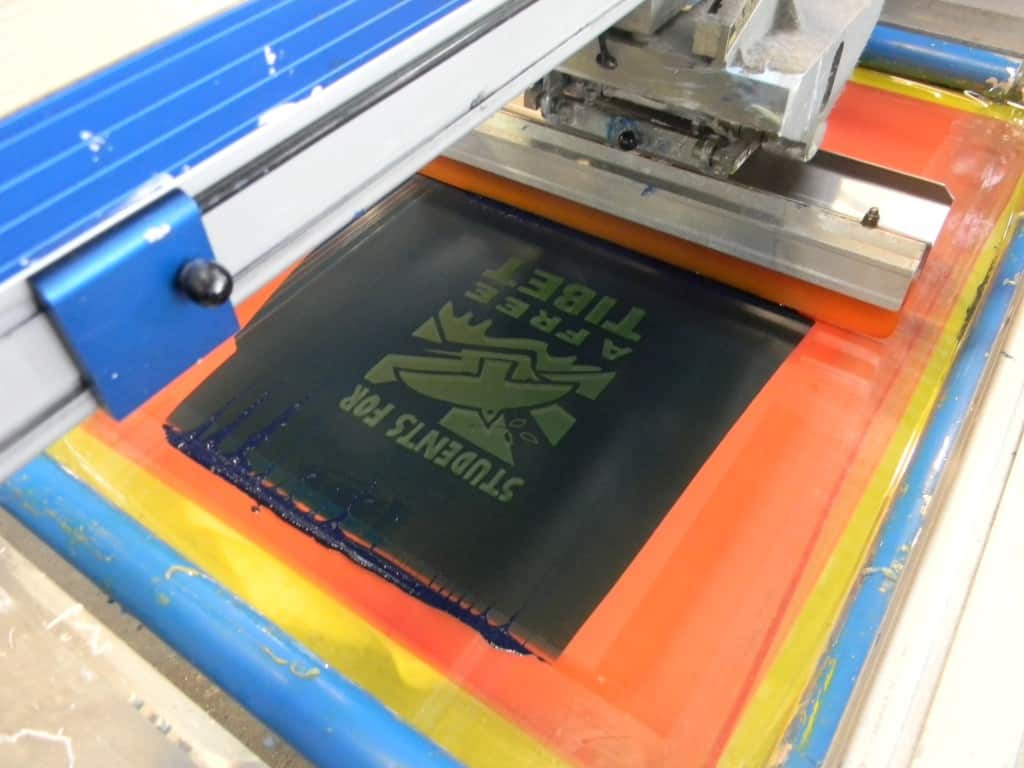

In this case we wanted the ink color dead on, so we swatched it on fabric and checked for Pantone match, cured that and checked again. And then printed it and checked it.

The we put the ink on the screen and printed it and basked in the glory of matching the color and also using up some ink that was lying around.

Finished product!

Celebrating using up some ink with a Sam Adams Rye Stout Growler!

Comments