Dye migration is when the color in a fabric (usually polyester or a poly blend) “migrates” into the ink you have printed. Just the other day in an airport I saw a group of people all wearing the same red golf shirts and the prints on them all were pink to varying degrees instead of what I am sure was supposed to be white. The red dye had gone into the white ink to ill effect.

How could a printer let such a thing leave their shop? The answer is that the process can take time, maybe not even be noticeable for a week or longer and I know I had one shirt that didn’t fully migrate for a year.

There are many solutions to combat dye migration, but the first step is identifying if it will happen and if so, to what extent?

Before you can get an answer to any problem, it is always best to define the problem. With dye migration, that means testing the fabric to see what you are dealing with.The plasiticizer used for the test costs maybe $40 or less for a quart and $80 for a gallon and either quantity will last you close to a lifetime of testing. Scraps of white fabric are free. A heat press won’t cost you more than a few hundred dollars if you don’t already have one. This cost is of course less than the jobs all of you have already ruined by not knowing you were going to have some red shirts turn some white ink into pink ink.

Ok, you have a shirt and it has some or all polyester content, what do you do? Too many printers I see P & P it. “P & P” is what I call “print and pray” and no matter what religion you do or don’t follow, I would keep prayer out of your printing operation. You need some science and here it is. You can test the fabric and get some idea of what the appropriate measures will be to print the fabric properly.

Can’t you just ask the garment manufacturer how to print their fabric? No, usually not. They just make the garments, and most leave it to you to figure out how to print it. That is changing and some mills and distributors are working increasingly to give the printer the information they need to properly print their garments. However, most times you are flying blind in this realm and there is a great deal at stake. If you print even fifty nice red hoodies and two weeks later the red dye gets into the white ink and turns it pink and the customer returns them, that has a hefty price tag. Make that 10K hoodies and you might be financially ruined.

Here is the test in words and then followed by some photos.

- Put the fabric you are going to test on the transfer machine which you have set at 320 degrees. Make sure the transfer machine has been turned on long enough to be fully warmed up!

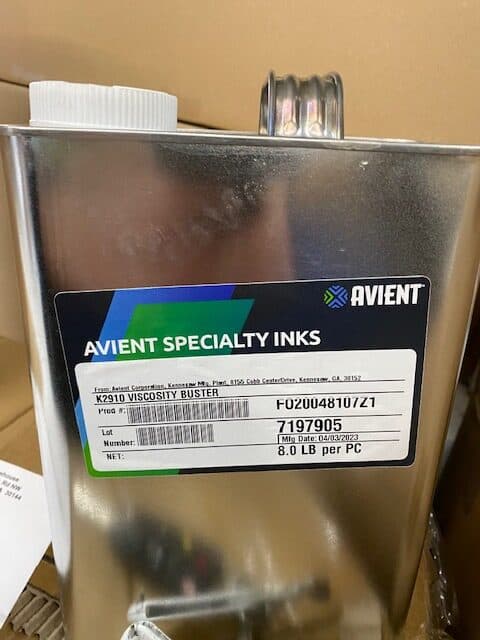

- Apply a quarter size spot of plasticizer. We use Avient Viscosity Buster, K2910. Basically you want only half of the plastisol equation, all plasticizer, no resin. If the reducer in whatever brand you use calls for no more than adding 1%, that’s usually the right stuff. The reducers that can be added up to 10% are usually curable reducers, they are NOT what you want. When in doubt, ask your supplier for the right product.

- Lay a piece of white cloth or pellon on top of the drop of plasticizer.

- Heat press (with your fully warmed up heat press) the white fabric on top of the fabric you are testing. Do it at 320 F (160 C) for 30 seconds.

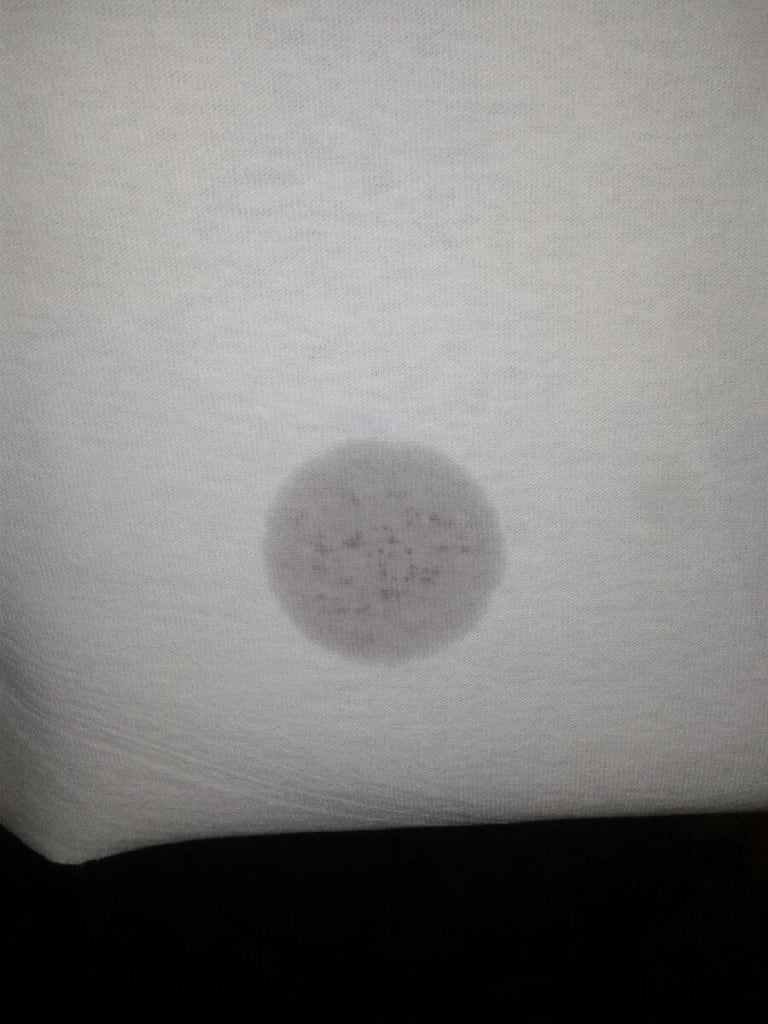

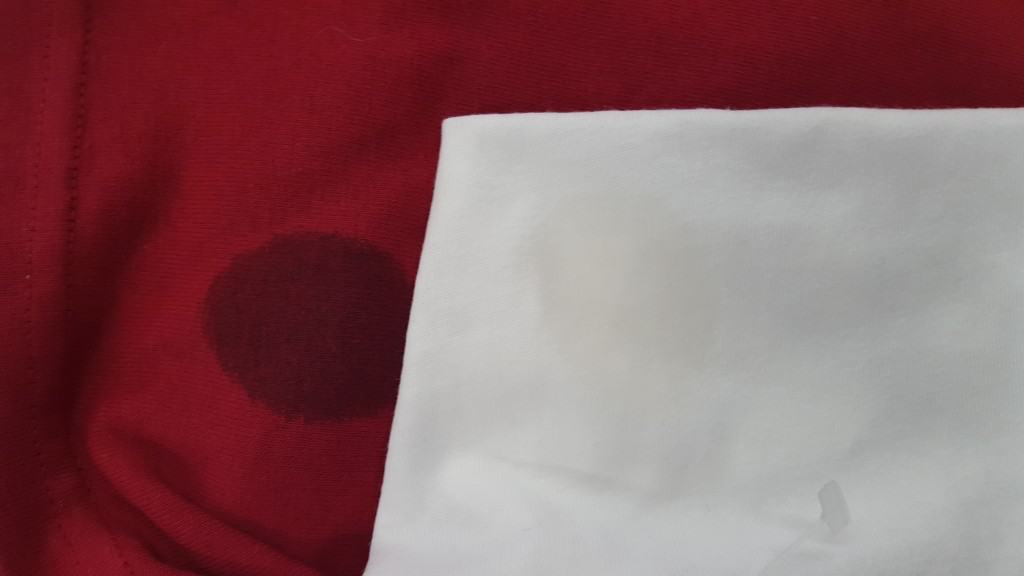

- Check the white fabric. What does that stain look like from where it was on top of the plasticizer? The more stain present on the white fabric the more severe the dye migration you will get when you try to print that fabric.

- Nearly all polyester dye colors will migrate at least a little bit, this test just lets you know how severe the dye migration is going to be.

- Test some fabrics you have printed before. Since there is always at least a tiny bit of migration, you need to get a feeling for how much stain is indication of how bad the migration is going to be. If you do this testing often enough and see how things then print, you eventually get a very good idea of how badly any particular fabric is going to have a dye migration problem and you can take the appropriate measures to combat it.

Comments