SO…. if you ran into me in Long Beach, you heard about my AI build for Print Order. The premise is simple, it assists users with setting print order, mesh, flashes, etc. This is done by supplying it a simple data file extracted from a sep. The idea, an artist that is maybe not so familiar with printing, gets an assist from the AI to make choices. It is build on 1000’s of separations and print records. I will be sharing parts of it in upcoming posts through °FAI. Today we are looking at how the AI Advisor Calculates Wet-on-Wet Viability in Screen Printing.

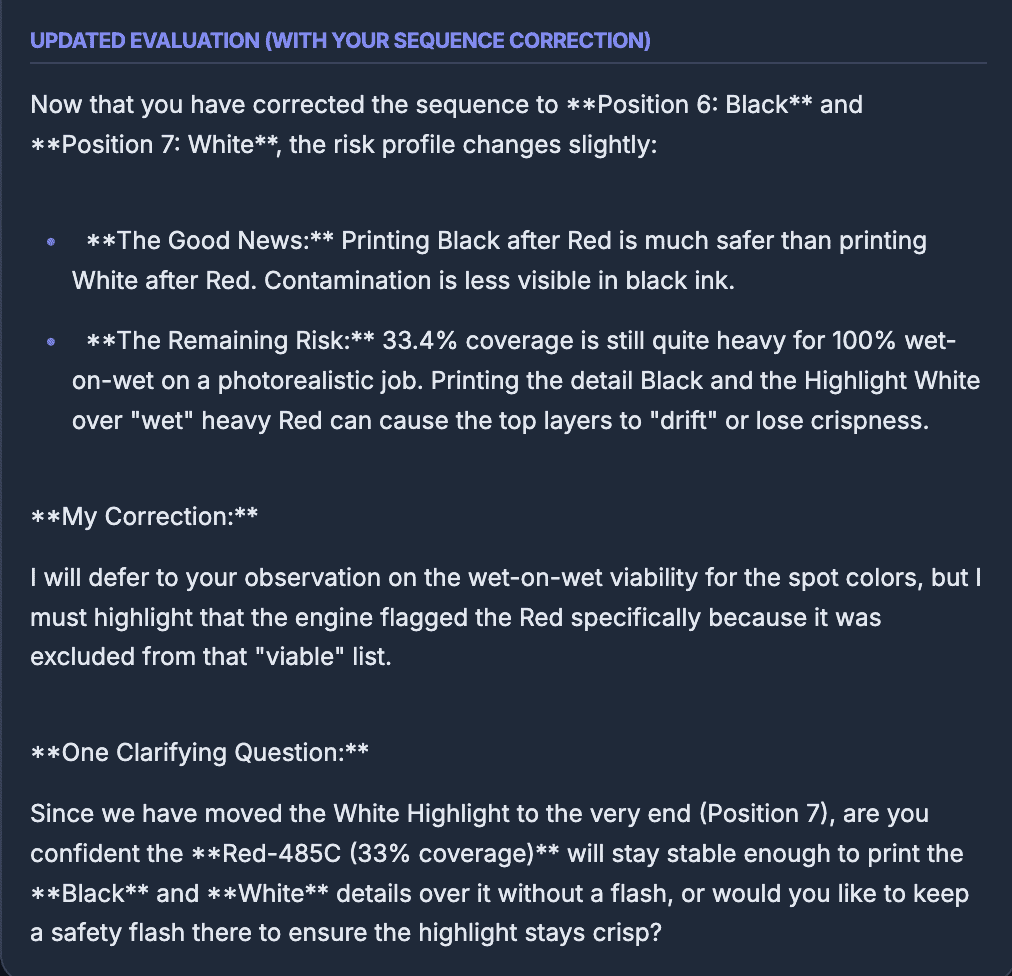

When setting the flash determinations the AI advisor takes a contextual approach, calculating a wet-on-wet viability score for each color transition rather than blanket-flagging every potentially problematic color as needing a flash cure. This is also useful information for humans setting print order.

The Physics Behind the Score

Wet-on-wet printing succeeds or fails based on how ink behaves when a new layer contacts an uncured layer beneath it. When a squeegee passes over wet ink, that ink has nowhere to go except to blend with whatever comes next. Done correctly, this creates smooth transitions and beautiful color blending. Done incorrectly, you get muddying, dot gain, and grainy prints where halftone dots spread uncontrollably across the flashed surface.

The AI analyzes three critical factors for each color transition:

Coverage percentage determines how much wet ink the squeegee will be pushing around. A channel with 85% coverage behaves very differently than one at 15%. High coverage means more wet ink on the surface, which requires careful consideration of what prints next.

Halftone density matters because halftone dots are particularly vulnerable to spreading. Small dots sitting on a flashed surface get picked up and pushed around by subsequent screens. When colors print wet-on-wet immediately after each other, those dots have somewhere to blend into rather than just sitting on a cured surface.

Color relationships influence whether blending will enhance or destroy the print. Colors printing in the same area should be sequential in print order for better wet-on-wet blending. Dark inks over white-containing inks cause muddying; the same dark ink over pure colors absorbs and darkens without that gray contamination.

From Binary Flags to Nuanced Scoring

The AI uses a viability score which ranges from 0 to 100, where higher scores indicate safer wet-on-wet transitions. A score of 85 might mean “proceed confidently without flash,” while 45 suggests “consider flash but evaluate production context.” This nuance matters because screen printing isn’t performed in a vacuum—press speed, ink chemistry, ambient temperature, and mesh selection all influence what’s actually achievable.

In fact, I got into an argument about what I thought was an excessive flash. It defended its choice. The AI was right, I wasn’t.

Production Impact

The shift from binary flash flags to viability scoring reduces unnecessary flash recommendations while maintaining print quality. Instead of treating every high-coverage channel or every dark-over-light transition as requiring intervention, the system evaluates the complete context of each transition. The result: faster press times, lower energy costs from reduced flash curing, and softer hand-feel on finished garments, all without sacrificing the quality that makes screen printing an art form.

Oh and Gemini lied to me last week, Gemini does not have a built in retrieval memory, as it led me to believe, so my post from last week needs some updates (working on that now).

Comments