Q: Is the ink dry on the shirt you printed?

A: It doesn’t matter.

Ink can be dry on a shirt and it will not last through a wash. Unless you are unethical and plan to leave the country after selling a shirt, you want the print to stay on the shirt beyond the first time it is washed.

Water-based ink often will dry (i.e. all the water goes out of the print) but it still via more time or more heat needs to totally have all the components cross-link or else it will come off the shirt in the wash.

Plastisol ink will gel and feel dry to the touch at about 250 degrees. However, if you don’t heat it to 320 degrees all the way through, the plasticizer doesn’t fully link with the resin and it will come off in the wash.

This of course can get even more complicated. You can put all kinds of additives in any kind of ink, and there are special inks as well. These all serve to change the equation of how long to apply heat, how much air flow you need, and to what temperature you need to get to. However, in the end you still need to see if the ink stays on the shirt when washed. I have heard it argued by chemists at ink companies that heavily catalyzed ink isn’t cured. However, if it is dry to the touch and doesn’t wash off the shirt, who give a flying you-know-what about whether it is cured?

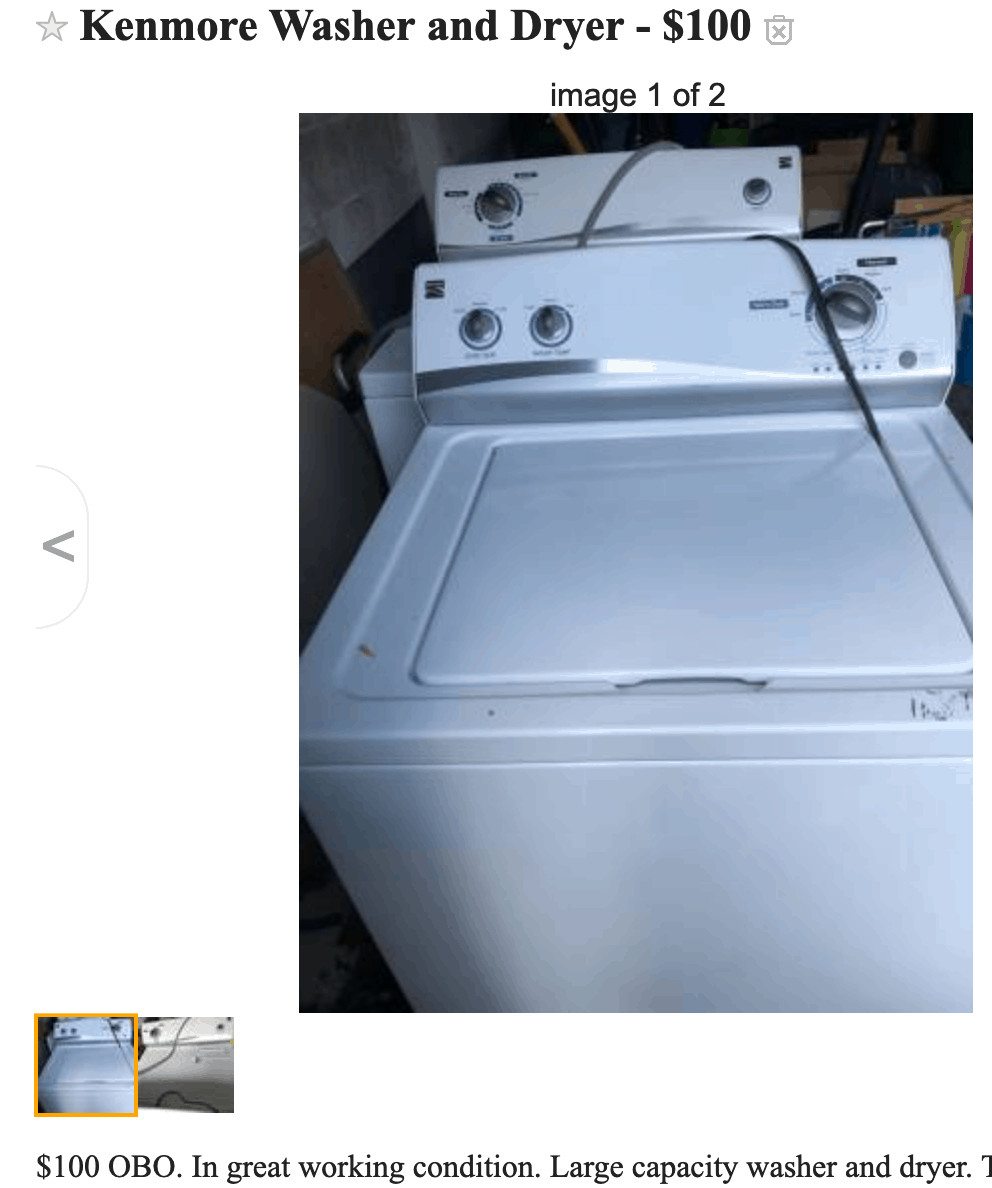

There are all kinds of tools to help determine whether the ink has cured: gauges on your oven (dryer,) heat guns (pyrometers,) donut probes (surface thermocouple,) heat tapes and chemicals. However, they are just tools and are not the ultimate test. You can also wait til the ink has cooled down and stretch the print and see if it cracks, but that’s not a full test. The test is the wash test, so either get a washer at work or regularly bring shirts to your home washer or laundromat.

If you are a big shop, consider an industrial machine that can program multiple washings and other settings, this will be machine used to measure the standards that big retailers will hold you to.

One last tip, if you catalyzed the ink, sometimes it can take up to four days to have full effect, so you might have to wait to do your wash test effectively.

Great information….we’ve had huge issues with this off and on. Thanks to your recent response to my cry for help I now have a “donut”, installed plumbing and electric, got a washer/dryer free on FB….both work!