We print mostly on material made from plants, and it is sewn and printed by living, breathing human beings. All of that means our work includes some diversity and is absolutely full of imperfections.

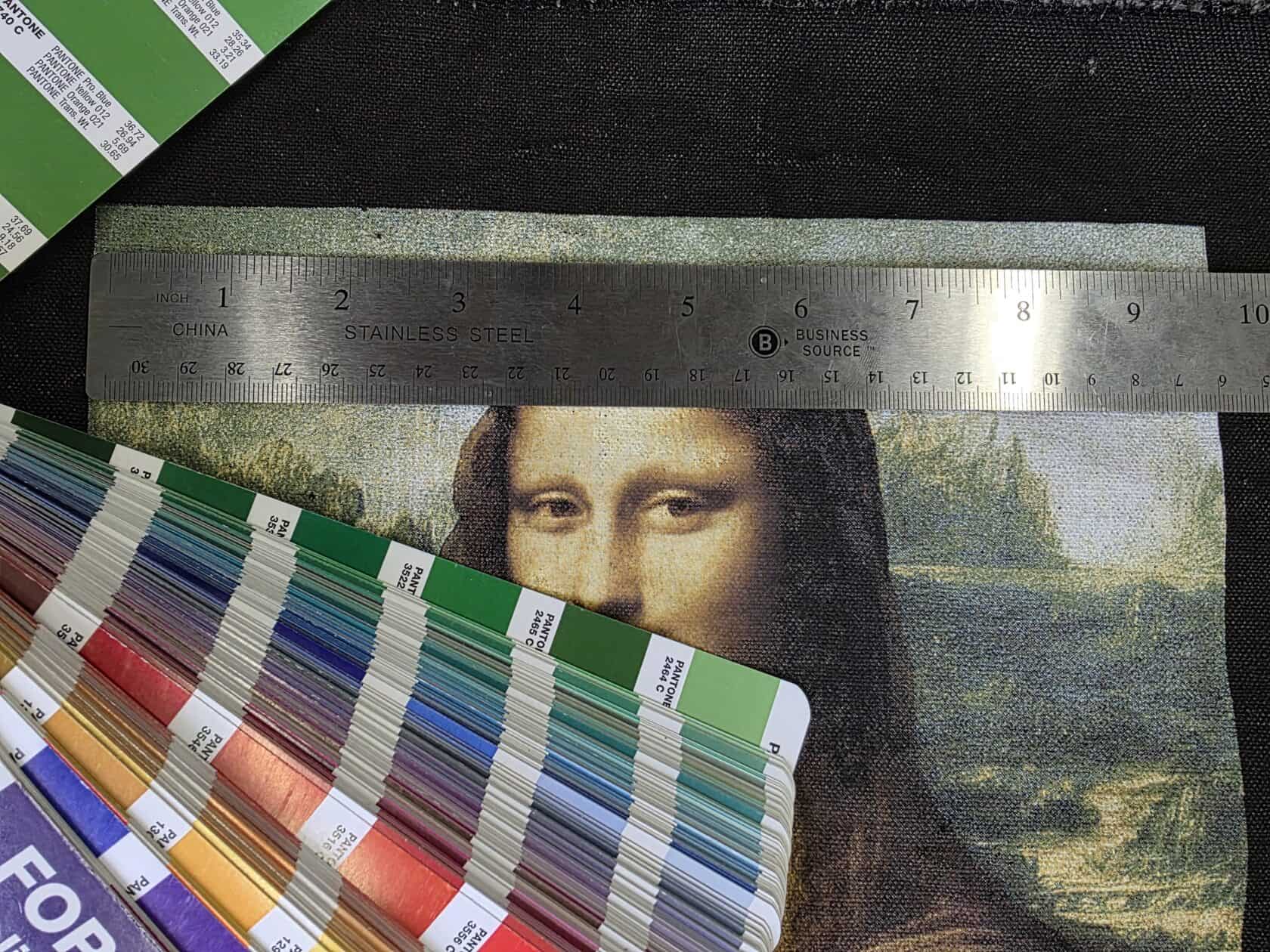

On the other hand, we are faced with customers operating with their perfect (actually not perfect) Pantone books, icy close stares, mockups backlit on their computer screens with the light of a thousand suns, some Platonic ideal in their heads of what they are going to get and, God forbid, their rulers.

The very best employees in a production shop are those who don’t continue to fuss when things are good enough, and who also don’t keep going when things are not good enough. That is a real skill. Only the best production workers can move fast and not have their work returned as defective.

Can I tell you exactly whether something is going to be good enough? No. But I can share some guidelines and advice to assist in your deliberations about whether something passes and should go out to the customer.

First, there are no universally accepted standards for color matching, error rate, crookedness, or exact placement. That is one of the things that makes this very hard.

Consider the following:

Who is the customer and what are their standards?

Some customers are easy going and realize things won’t be perfect and that everyone’s goal is good enough and will it sell. Others are corporate and exacting and you have to learn that over time and sometimes painfully so. If a new customer start by asking what previous printers got wrong.

How will the shirts be seen?

Are they all going to be on display together, or bagged and shipped all over creation? If they are being dispersed, slight variations matter less because no one will compare one shirt to another.

Get a neutral opinion when needed.

Sometimes it helps to have someone with no stake in the process weigh in. Show a regular customer or someone passing through what you printed and see if they notice what you are worried about.

If something is clearly wrong, reject it.

If it is very clearly too low, off center, or crooked then reject it. Otherwise you will violate the commandment: don’t let them get out the ruler.

Once a customer starts measuring, nothing is perfect and you can end up in a very bad place.

If the design itself is ugly, be extra careful.

If something is ugly, you had better get it thoroughly signed off. If it’s ugly, it needs to be printed perfectly.

If someone down the line says “that’s ugly,” they can’t return it for ugliness, but suddenly the ruler or Pantone book comes out and they may try to return it for other reasons. Don’t leave that door open.

High standards can build trust.

Sometimes handing a customer a couple of “rejects” (lets not call them that, they are imperfect…) and watching them fail to see anything wrong puts you in a very good place. It builds trust in your judgment and standards.

Act quickly and decisively.

Things won’t get better on their own. Don’t hide from the potential error. Speak to the customer as soon as you can despite how hard it may be. Don’t bullshit them, be honest, and work toward resolution. Realize that problems solved successfully whether by discount, reprint, repair or replacement are going to be why a good customer stays with you. Things will always go wrong and the question is for them, what happens when it does?

Protect your reputation.

Your reputation is one of the most valuable things you own and one of the easiest to ruin. It is far easier to keep it than to repair it. Don’t bury clearly bad shirts in a bundle of good ones. Own up to clear mistakes. Don’t let your customer look bad to their boss or to their customers. At the same time, learn how to guide a customer who may be over critical, this can build trust.

Sometimes discretion is the better path.

There are times when something is not quite perfect but you know the end user will not care. If you raise it, your client may feel obligated to act when no one actually benefits.

That is a tough judgment call, but it does come up.

In the end, this work requires judgment. There is no chart that replaces experience and care. Move fast, pay attention, ask questions when needed, and remember that our goal is always the same: work we are proud to send out and customers who trust us to make the right call.

This is craft work done by humans for humans. Perfection is not the goal, judgment is. Know when to push, know when to stop, and always protect the shop’s reputation. If you can do that while moving quickly and calmly, you are operating at an elite level.

Comments