Our Field Trip to Rutland

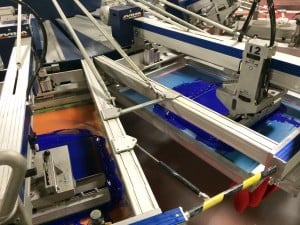

Rick and I are on a tour of North Carolina and South Carolina this week. Today we visited the Rutland Group. We’ve both been loyal Rutland ink customers for years and I must say, this being my first visit, it was really something to finally see where the magic happens. Though our hosts were more than…