Poly White vs. Low Bleed White: If you’ve been in screen printing long enough, you’ve watched the dye migration battle escalate, and our options for overcoming it, grow.

So What’s the Difference?

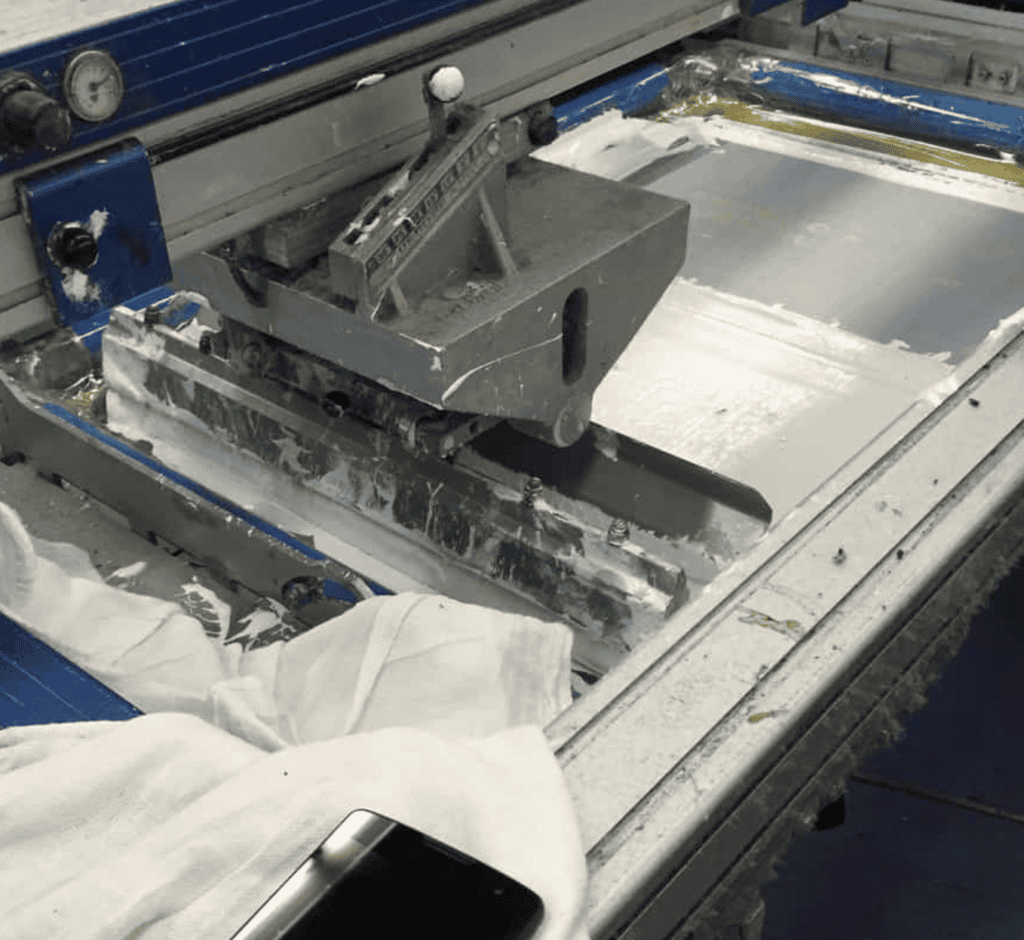

Here’s the breakdown. Low-bleed white covers any white ink engineered to resist dye migration. Manufacturers originally created these inks for 50/50 cotton-poly blends, where standard cotton whites tend to bleed. Low-bleed whites usually deliver high opacity for fabrics that need moderate bleed resistance. They print smoother, creamier, and softer to the touch. Printers use LB white as both an underbase and a top white. Most formulas cure around 280°F.

“Poly white” is the heavy-duty version within that category, engineered specifically for high-polyester content garments where standard low bleed whites fail. Poly white is often a flexible temperature cure ink for 100% poly and Poly Blend fabrics. When printing on fabrics that exhibit unstable dyes, this ink allows you to drop the cure temperature as low as 270F to 320F offering better dye migration control. Some of the inks on the market cure at even lower temps.

Having said all that, LB (low bleed), Chill, LC (low cure), rapid cure, cooling, etc – these terms get thrown around, so the TDS (technical data sheet) is the most important part of choosing an ink. Knowing what fabrics you want to apply it and what the is the intended outcome. A simple Dye Migration Test, can help with those choices.

Think of it as a spectrum. Cotton white sits at one end (no bleed resistance), standard low bleed white handles moderate challenges like 50/50 blends, and poly white, sits next, blocking dye migration from some 100% polyester and problem garments that defeat lesser inks. Finally, you can use an actual migration blocker (grey blocker or black blocker) under a LB or Poly white. For the really tough fabrics like sublimated camo, two blockers may be necessary, and you should either use two different mesh counts, or angle one of the mesh (if you stretch your own) so that the barrier is interlocking versus stacked. Pure black blockers are my favorite, because the hand is usually less, and the migration blocking capability is usually high.

When to Use LB or Poly White

Consider poly white for bleeding 50/50 shirts, garment-dyed pieces with dye migration issues, and especially 100% polyester garments where dye migration is almost guaranteed.

The Advantages:

Poly skips the grey under base in many situations, critical when you don’t have enough stations available or need a softer hand than grey provides. They print through higher mesh counts than barrier grey inks.

The Trade-offs:

Light-colored cotton shirts (particularly greens and blues) can develop ghosting if stacked while hot. The LB/poly white’s chemistry bleaches the fabric beneath. Fix this with longer dryer outfeeds, lower temps, smaller stacks, or cooling fans. The hand and printability also suffer compared to cotton whites, though poly white still outperforms barrier grey.

Comments